The cement industry has an essential role in developing housing and infrastructure. It is also quite critical in the overall economy with the level of employment it provides and is effective for the Gross Domestic Product (GDP). However, the cement industry is energy-intensive. As global urbanization and economic development increase the demand for new buildings and infrastructure, the need for cement will also increase and trigger urban air pollution through its excess production.

While cement production creates a significant amount of dangerous gases in the air, the industry can be considered one of the primary sources of anthropogenic air pollution, with dust dispersal at many stages of production. Cement will continue to be essential for expanding global economies facing growing housing and modern infrastructure needs (Abu-Allaban & Hani, 2011). The Global Economic and Climate Commission estimates that $90 trillion will be invested in infrastructure by 2030, with two-thirds of this investment in developing countries (Lehne & Preston, 2018). Therefore, the cement industry can be considered the primary field of study in the development of green manufacturing.

Reducing carbon emissions is very important in minimizing climate change’s impact. It is one of the most fundamental global problems of today and the future. With the Paris Climate Agreement ratified by the European Union and 179 countries, businesses must change this direction. Cement production emissions significantly contribute to global warming and climate change (Devi, Lakshmi, & Alakanandana, 2017). To align the cement industry with the Paris Agreement on climate change, its annual emissions must decrease by at least 16% by 2030 (Lehne & Preston, 2018).

The cement sector is also included in the first five sectors to be evaluated within the Carbon Border Adjustment Mechanism (CBAM), announced by the EU with Fit for 55. The export of the cement sector from Turkey to the EU is significant (URL 2). This will severely affect cement manufacturers’ overall business planning and growth strategies. However, only limited progress has been made so far. Cement manufacturers can take advantage of being a pioneer in the sector by taking “green” actions with technological developments.

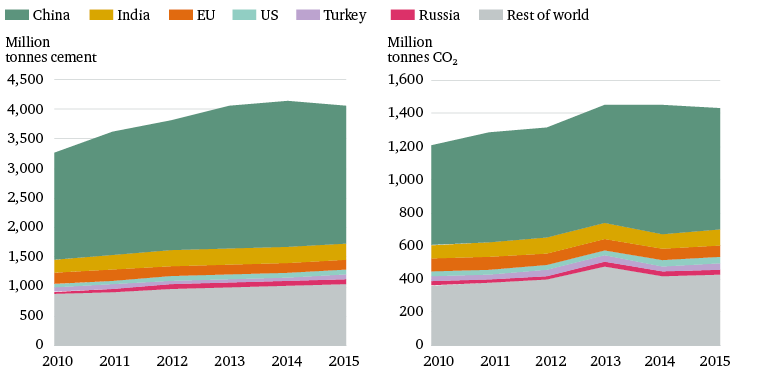

Industrial plant chimneys of cement and construction companies significantly contribute to poor air quality. As of 2007, Air Quality Resources reported that the cement industry produced 5% of the total greenhouse gases in the atmosphere (Zimwara, Mugwagwa, & Chikowore, 2012). In 2015, it had approximately 2.8 billion tons of CO2, equivalent to 8% of the global total.

If the cement industry were a country, it would be the third largest emitter after China and the USA (URL 3).

The cement industry faces many challenges due to environmental concerns and sustainability issues. To mitigate its effects and advance, ecological issues arising from the operations should be well known. The cement industry should minimize its environmental footprint throughout the production cycle. As regulations on emission limits continue to tighten, manufacturers need to be vigilant in reducing their gas and particulate matter emissions. Therefore, it is necessary to continuously monitor the air by automatic control systems to detect and mitigate the emission pollution sources in the production facilities.

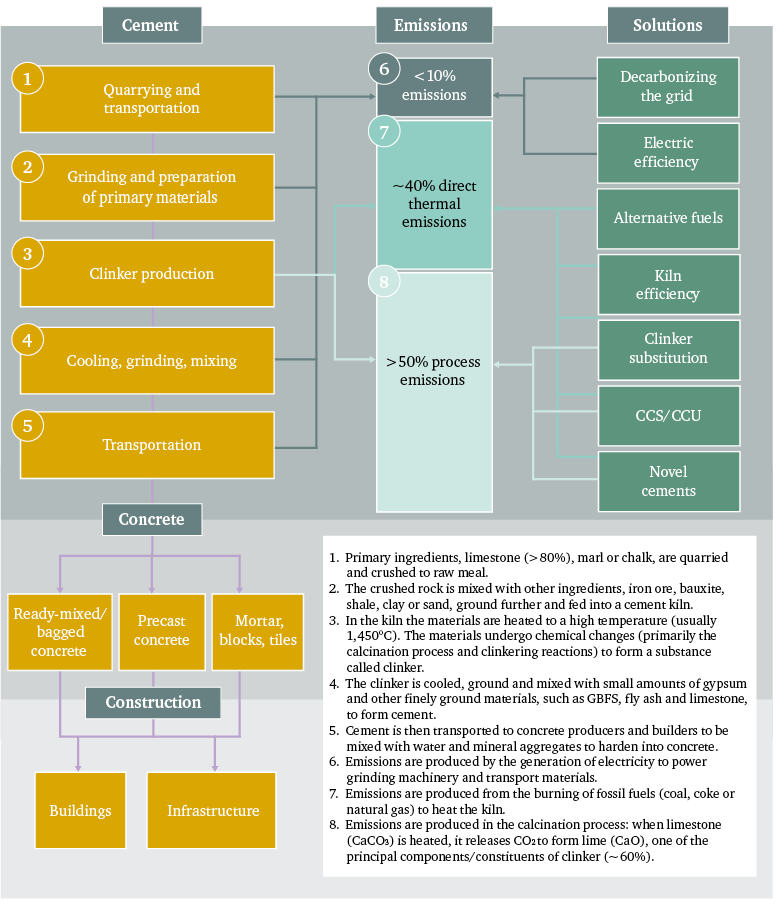

The cement industry standard is one of its types, called Portland cement. With 4 billion tons produced yearly, it is used in 98% of today’s concrete. The production of Portland clinker, which acts as a binder, is crucial in making Portland cement. Limestone (CaCO3) is “calcined” at high temperatures in a cement kiln to produce lime (CaO), leading to the release of waste CO2. About half of the emissions from cement are process emissions from this reaction (Lehne & Preston, 2018).

In the cement industries, dust is emitted from stockpiles, quarries, transport of raw materials, kilns operation, cooling, and clinker grinding. Oxides of carbon, nitrogen, and sulfur are mainly produced by the combustion of fuel for power generation (Abu-Allaban & Hani, 2011). Dust emissions constitute a large part of the air pollution problem in production. Workers in these manufacturing facilities and citizens living in the region are exposed to the harmful effects of dust and particulate matter (PM).

As a result of exposure to particulate pollution, people are more likely to develop various diseases such as the heart (non-fatal heart attack, irregular heartbeat) and lung (severe asthma, decreased lung function, irritation of the airways, increased respiratory symptoms such as coughing or difficulty breathing). Children and the elderly are identified as the individuals most likely to be affected by particulate matter exposure. Considering the adverse environmental effects of dust particles, they can be carried by wind over long distances and mixed with the ground or water. It can cause acid rain by affecting the damage to sensitive forests and vegetation and the diversity of the ecosystem (Duran, Erdem, & Doğan, 2021).

Continuous monitoring of air emissions in production facilities in the Regulation on Control of Industrial Air Pollution is also of interest to the cement industry. The enterprises cover the costs of the measurements required according to the legislation. Low-cost, cloud-based sensors strongly correlated with reference stations should be employed to provide the validated air quality data at a minimum cost. In this direction, a result of continuous measurements made with sensors that can be placed at many points, sensors can create a high-resolution Spatio-temporal pollution map. With intelligent data correction and calibration through state-of-the-art artificial intelligence, models can establish a healthy environmental monitoring system.

Cement is one of the primary inputs of concrete, which is described as the second most consumed material in the world after water (Hasanbeigi, Price, & Lin, 2012), and will continue to be in our lives in the coming years due to its versatile, flexible, ease of production, low cost and durability (Lehne & Preston, 2018). However, alternative materials often have a higher carbon footprint. (Lehne & Preston, 2018). Therefore, making these materials more sustainable remains critical. Thus, the energy efficiency of cement plants can be increased, alternatives can replace fossil fuels, and CO2 can be captured and stored. In addition, air quality management is required to manage air pollution concerns in production facilities effectively. Increasing the service quality by protecting the health of employees and the public will also increase competitiveness and profitability.

References

Abu-Allaban, M., & Hani, A.-Q. (2011). Impact Assessment of Ambient Air Quality by Cement Industry: A Case Study in Jordan. Aerosol and Air Quality Research, 11(7), s. 802–810.

Devi, K., Lakshmi, V., & Alakanandana, A. (2017). Impacts of Cement Industry on Environment-an Overview. Asia Pacific Journal of Research 1, s. 156–161.

Duran, Z., Erdem, B., & Doğan, T. (2021). Particle Material Release in Open Mining Operations: Literature Research. Journal of Eskişehir Osmangazi University Faculty of Engineering and Architecture, 29(3), s. 450–465.

Hasanbeigi, A., Price, L., & Lin, E. (2012). Emerging Energy-Efficiency and CO2 Emission-Reduction Technologies for Cement and Concrete Production: A Technical Review. Renewable and Sustainable Energy Reviews, 16(8), s. 6220–6238.

Lehne, J., & Preston, F. (2018). Making Concrete Change: Innovation in Low-carbon Cement and Concrete. Chatham House Report Series.

Zimwara, D., Mugwagwa, L., & Chikowore, T. (2012). Air Pollution Control Techniques for The Cement Manufacturing Industry: A Case Study for Zimbabwe. CIE42 Proceedings, 37, s. 1–13.

URL 1: Cyprus Museum by Zaha Hadid Architects. 9 February 2022.

URL 2: ICI Sustainability Roadmaps: Border Carbon Regulation Obligations Come to the Fore in Mineral, Stone and Soil Products. 17 February 2022.

URL 3: Q&A: Why Cement Emissions Matter for Climate Change. 9 February 2022.

URL 4: Cement Production Increased 33 Percent in The First 2 Months. 9 February 2022.