Mining is one of the most critical sectors that constitute a significant portion of the world economy. Unfortunately, due to the nature of its production stage, environmental problems arise. One crucial problem affecting the health of the public living around those sites is air pollution. Pollutants released during the production cycle are the main reason for this health problem. It is possible to minimize its contribution to climate change with new clean energy models. The mining industry plays a crucial role in producing the metals and minerals required to transition to these energy models. This sector contributes to the net-zero target and needs to handle economic development and environmental protection together.

While climate change threatens the ecological balance, air pollution is the main reason for 7 million premature deaths yearly (WHO, 2021). We need to minimize our environmental footprint to leave a livable environment for future generations. As the August 2021 IPCC report clarifies, it is essential to de-carbonize the global economy as quickly as possible to address these issues. This requires a new transformation. The decision to leave out coal at COP26 made it mandatory for countries to turn to use clean energy types (United Nations Climate Change, 2021). This means that other metals and minerals (Lithium, graphite, cobalt, nickel, etc.) will be used instead of coal as an energy source. By 2040, mineral requirements for clean energy technologies are expected to quadruple (URL 1). In fact, this situation will not reduce the development of the mining sector with its current decision to exit coal; on the contrary, it will ensure its economic growth is more significant than other sectors.

The economic models that change according to the conditions of the new world also bring about changes in trade. The European Union aims to be climate neutral by 2050, that is, to zero its net greenhouse gas emissions (European Commission, 2020). In this direction, it has developed the Border Carbon Adaptation Mechanism to include other countries in the fight against climate change. This system can be understood as the extension of the intra-EU Emissions Trading System (ETS) outside the EU with the simplest definition. Since 2005, the EU ETS has been concerned with regulating emissions from factories and power plants in energy and carbon-intensive sectors such as electricity, paper, cement, iron and steel, petroleum products, chemical products, and air transport (Aşıcı, 2021). Since the mining industry is also affected by this system, investors need to de-carbonize their facilities as soon as possible. According to a data source from 2020, mineral exports in Turkey meet 2.53% of general exports (URL 2). Turkey is rich in resources, enabling the mining industry to develop rapidly and have an essential share in exports. Reducing or even not emitting greenhouse gases in the production cycle is necessary to turn this situation into an advantage.

Nowadays, enterprises’ environmental and social performance is one of the most critical points in global trade. Minimizing the environmental impacts of mining activities is necessary to contribute to sustainable development and solve various environmental and social challenges that harm local communities and disrupt supply. Thus, one of the steps companies should take is to manage the air quality in the mine sites.

From the discovery of an ore formation to the site’s abandonment, the mining process takes place in 5 primary stages. Prospecting, development, production, and rehabilitation (Beşir, 2015). In its most general form, mining activities are carried out in two ways, underground and above-ground. Particularly, Particulate Matters (PMs) and Methane (CH4) gas emissions in open and underground mining constitute a large part of the air pollution in mining areas. In addition to the dust resulting from the blasting activity in surface mining, some gases are also emitted into the atmosphere as a result of the chemical reaction that occurs due to the use of explosives on the sites. These are CO2, H2O, N2, CO, NOx and SO2 (Beşir, 2015).

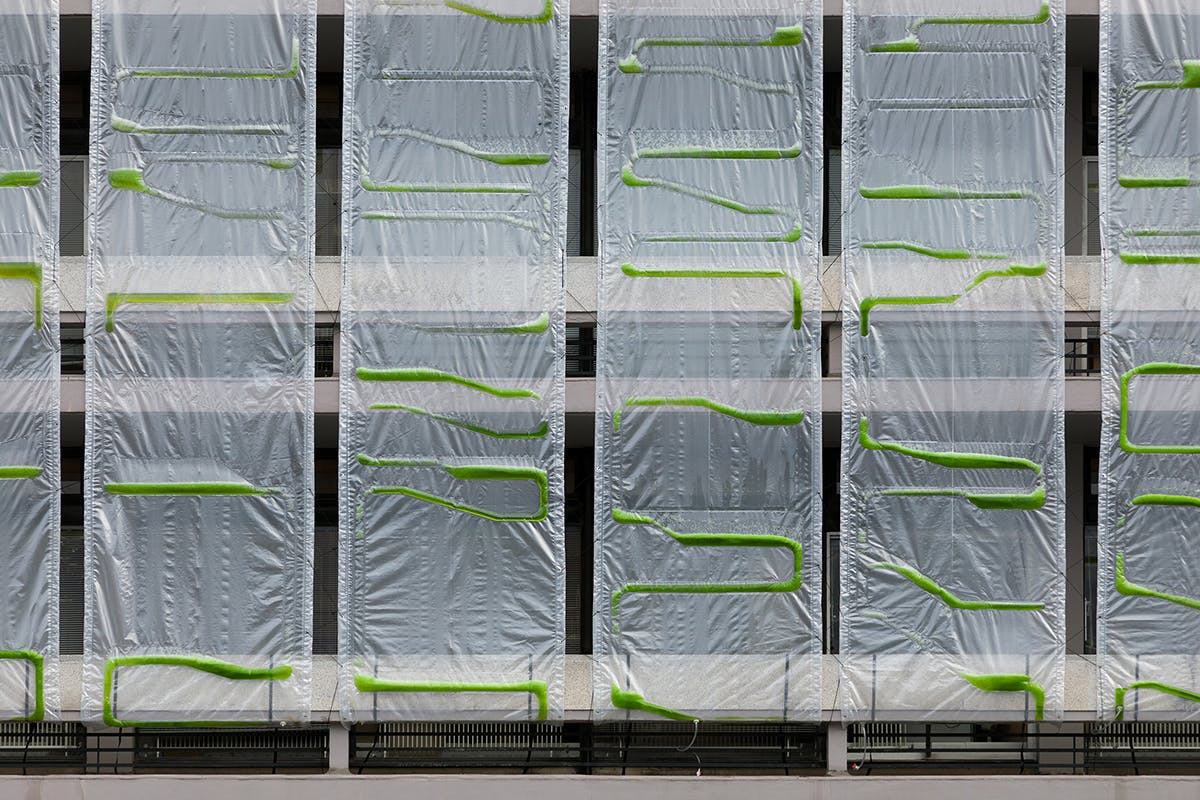

Gases released during mining activities negatively impact workers’ health at the mining site. Occupational diseases caused by exposure to respiratory pollutants are among Turkey’s most common occupational diseases. It is estimated that people working in the mining industry are more likely to get occupational diseases due to their exposed pollutants (Taner & Özdemir, 2012). In line with the goal of zero harm to occupational health, it is important to determine elements that may cause air pollution in production. To protect workers from unavoidable exposure to dust, it is necessary to identify and analyze risks by making as many measurements as possible. Thanks to advancing sensor technology, it is easy to monitor air quality levels at every production stage. It is possible to make the working and environmental conditions of the enterprises healthy and safe by examining the ecological effects of mining activities with cloud-backed continuous measurement systems.

It is possible to reduce the factors that cause air pollution in the mining sector to a certain acceptable level. Therefore continuous measurement should be utilized depending on the emission source; the source should determine PM releases/factors, and by type of activity should apply dust reduction techniques. Thus, the regions around the enterprise that are also affected by these exposures can be prevented (Duran, Erdem, & Doğan, 2021). It is essential to evaluate the limit values specified in the Regulation on Control of Industrial Air Pollution and plan preventive/reducing measures for adverse effects.

The mining industry has an essential responsibility in the transition to clean energy. It has been and will continue to be in many areas of our lives and needs to be redesigned to be compatible with Paris Agreement. For the production and processing of environmentally friendly and sustainable mineral resources, the prevention of air pollution has great importance in terms of environmental health, the health of local communities, and competitiveness in trade. In trade agreements, besides the product’s quality, the operators’ environmental effects during production are also taken into account. In today’s world, it is possible to manage air quality with minimum cost thanks to advancing sensor technology, and businesses are expected to have environmentally friendly production processes.

References

Aşıcı, A. A. (2021). The European Union’s Border Carbon Adaptation Mechanism and the Turkish Economy. Istanbul Policy Center.

Beşir, A. Ç. (2015). Evaluation of Particulate Matter Emission Factors Used in Surface Mining Within Turkey And International Applications.

Duran, Z., Erdem, B., & Doğan, T. (2021). Particulate Matter Release in Open Mines: A Literature Search. Journal of Eskişehir Osmangazi University Faculty of Engineering and Architecture, 29(3), s. 450–465.

European Commission. (2020). A European Green Deal.

Istanbul Chamber of Industry. (2021). Mining, Stone and Soil Products Industry Sustainability Priorities, and Tracking Indicators.

Taner, S., & Özdemir, U. (2012). The Effects of Air Pollution on Workers’ Health In Different Work Places. Journal of History Culture and Art Research, 1(4), s. 190–198.

UNEP. (2020). Sustainability Reporting in the Mining Sector.

United Nations Climate Change. (2021). COP26: The Glasgow Climate Pact.

World Health Organization. (2021). WHO Global Air Quality Guides Press Release.

URL 1: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions/executive-summary The Role of Critical Minerals in Clean Energy Transitions. 01 March 2022.

URL 2: https://www.mta.gov.tr/v3.0/bilgi-merkezi/maden-dis-ticaret-payi Share of Mining in Foreign Trade. 01 March 2022.

URL 3: https://www.begodelmepatlatma.com/bolge-corlu-delme-patlatma-sirketi-153 01 March 2022.

URL 4: https://dailytechnonewsllc.com/effective-dust-and-noise-monitoring-essential-to-worker-safety/?feed_id=3268&_unique_id=61b8bc6e002d8 Effective dust and noise monitoring essential to worker safety. 01 March 2022.